The Genesis of Mass Production at Highland Park

The offshoot of scientific management – mass production – was put into practice for the first time around 1913. Only later in 1926 did Ford articulate it as “focusing upon … the principles of power, accuracy, economy, system, continuity, and speed.” How mass production fit in with organization and the market was further articulated by Ford in this way:

The interpretation of these principles, through studies of operation and machine development and their coordination, is the conspicuous task of management. And the normal result is a productive organization that delivers in quantities a useful commodity of standard materials, workmanship and design at a minimal cost. The necessary, precedent condition of mass production is a capacity, latent or developed, of mass consumption, the ability to absorb large production. The two go together, and in the latter may be traced the reasons for the former.17

The assembly line that followed, contrary to popular thought both then and now, was not simply the idea or the result of the efforts of Henry Ford alone. During a tour of Henry Ford’s Rouge, I watched a film on the history of mass production that gave total credit to Henry Ford for both the concept and implementation of this system of manufacturing. The film, shown every day to thousands of visitors, perpetuates a lie; for there were many unnamed individuals who contributed to what became mass production at the Ford Motor Company.

Indeed, James Flink summarized the story as one in which mass production developed upward from the shop floor rather than downward from Henry, with key individuals that included skilled tool makers like Carl Emde and staff members C. Harold Wills, Joseph Galamb, Charles Sorenson, Clarence Avery, William C. Klann, and P. E. Martin.18 It was this group and others, who through experiment and trial and error gradually perfected a way of making automobiles at the Highland Park factory. Fixed work benches, where the assembly of component parts took place, gave way to a series of positions along a moving line where one small component after another was added.19

Scientific management had an enormous influence on the nature of American life during the early twentieth century, and nowhere was that more obvious than at the Ford’s Highland Park factory. It was there that by trial and error Ford and his team of engineers and mechanics developed the system of dragging a car chassis across the floor to stations where parts, brought by pulley, conveyor, or inclined plane were bolted on. Unlike the Model T itself, the assembly line took time to develop to a level of perfection, as numerous improvements to the line were implemented during the T’s 18-year production run. Ford applied four basic principles to increase efficiency: the work must be brought to the man; the work should be done waist high to eliminate lifting; waste motion, human or mechanical, must be minimized; and finally, each task must be reduced to utmost simplicity.20

The impact of the assembly line at Ford was staggering, as the volume of production was unprecedented and cost reductions unparalleled. Once governed by skilled mechanics, the shop floor was conquered by scientific management and the assembly line. This process was nearly completed by 1914.

Joyce Shaw Peterson has described the creation of the assembly line as a series of processes that began with arranging production in an orderly sequence and ended with the development of overhead conveyors. By 1913 an assembly line operated at Ford, and by 1916, helped by Ford’s openness to journalists and visitors, it was institutionalized in various forms throughout the automobile industry. The gradual perfection of the assembly line inaugurated a second phase of automobile production between 1908 and 1925, and which produced the Model T in volume. It entailed rigid standardization, extensive division and subdivision of tasks, and progressive line production. It was an inflexible process, as opposed to a more flexible mass production system that emerged in the late 1920s. Under Fordism, semiskilled/unskilled workers operated highly specialized machines. In 1910, nearly 75 percent of all jobs were classified as skilled work, but by 1924 expert work declined to 5 to 10 percent.21 The development of machine technology was crucial to control of the production process because it eliminated the need for strength or training. James Flink explained that, “Fordism meant that neither physical strength nor the long apprenticeship required for becoming a competent craftsmen were any long prerequisites for industrial employment. The creativity and experience on the job that had been valued in the craftsmen were considered liabilities in the assembly-line worker.”22 Furthermore, Flink lamented that “the American myth of unlimited individual social mobility, based on ability and the ideal of the self-made man, became a frustrating impossibility for the assembly-line worker.”23 Dexterity, speed, and concentration replaced craft and experience.

By 1913, a majority of workers were semiskilled or unskilled and operated a highly specialized machine that nearly eliminated the “human element.” The process is evinced in Arnold and Faroute’s observations in Ford Methods and the Ford Shops: “When the moving-assembly line was placed in work with 29 men, splitting the one man operations into 29 operations, the 29 men began turning out 132 magneto assemblies per hour, or 1,188 per 9-hour day, one man’s time producing one fly-wheel magneto assembly in 13 minutes 10 seconds, a saving of 7 minutes time on each assembly or more than one-third of the best one-man time.”24

In addition to descriptions of the production process, Arnold and Faroute took iconic photographs of Ford’s workers, but their “classic” observations were about machines, not laborers. In a description of “Assembling the Steering and Front Axle,” they wrote, “there are two operations to be performed: (1) to press the arm in its seat in the sub-axle hub boss; (2) to screw the nut on the threaded end of the steering arm.”25 No attempt was made to describe the three men in the photograph.

The assembly line initiated what scholar Harry Braverman has called the “degradation of work.”26 Braverman’s thesis was subsequently modified and pursued by sociologist David Gartman in Auto Slavery: The Labor Process in the American Automobile Industry, 1897-1950.27 Gartman asserted that the assembly line was born of class antagonisms rather than a technological rationality. Motivated by the “narcotic” of profit, capitalists wrestled production away from the craftsman. The craftsmen, having lost the ability to control pace and accuracy, became vulnerable to exploitation. Labor was reduced to repetitive, mindless motions. To vindicate his thesis, Garman distinguished between “repressive” capitalist and “non-repressive” natural controls of labor. Finally, bureaucracy and occupations were created to buttress the capitalist order, and gave birth to the modern corporation.

Marxist sociologists have enhanced the view of the assembly line, but historians have revealed that what happened at Ford’s plants was a complex social process. The reactions of workers to monotonous labor defy simple Marxist explanations. Historian Joyce Shaw Peterson wrote:

Scholars analyzing the labor process in capitalist industry have sometimes seen the progressive deskilling of jobs as synonymous with the degradation of labor. There is no question that deskilling characterized the development of the automobile industry during its successful emergence as a “giant enterprise.” The question concerns how that deskilling was experienced by the workers themselves, whether as progress, or loss, or something else entirely. No single answer to this question is possible. Those workers for whom deskilling was experienced as degradation . . . were those who personally lost the need for their particular skills and saw their pride in workmanship diminished as machines took over their jobs and their own autonomy was diminished by a division of skills and increased management planning. For these auto workers degradation was very real, diminishing their pride and status and undoubtedly contributed to making them the most militant and union conscious of their fellows. Such workers comprised a minority of the workforce. Much more common was the experience of the auto worker for whom machine tending replaced simple heavy labor or the semi variegation of farm work. Not only could such workers make more money as automobile workers, but they also experienced their work itself as more modern and sometimes identified with the skill of their machines and indeed with their own skill in running them.28

Personal responses to working on the assembly line are difficult to assess historically, but whatever took place on the microscopic scale, Fordism transformed the social relations of the macroscopic work place. The individual became anonymous, and the division of labor reduced tasks to mindless repetitive actions. Peterson noted that visitors lamented at the monotonous labor, but the worker’s response was “complicated, as it could not be a simple choice between monotonous, repetitive tasks, and challenging interesting work . . . no such choice was offered.”29

While the assembly line contributed to the “degradation of work,” the opportunity to labor brought workers from Southern and Eastern Europe, the American South, and Mexico to the Midwestern United States. This opportunity was particularly powerful for Mexicans and African Americans.30 In 1900, the population of Detroit was half native-born Whites, and half immigrants from northern and western Europe.31 By 1913, the workforce included Russians, Poles, Croats, Hungarians, and Italians.32 The workforce also came to include social outcasts. In 1919, “the Ford Motor Company employed hundreds of ex-convicts and 9,563 ‘substandard men’ – a group that included amputees, the blind, deaf-mutes, epileptics, and about 1,000 tubercular employees.”33 In contrast to Gartman, Meyer argued that “between 1908‑1913 Ford officials gradually discovered that workers required just as much attention as machines and the flow of materials.”34 The droves of workers were not “completely plastic and malleable,” and “as Ford mass production became a reality, Ford officials and managers gradually uncovered a massive labor problem.”35

To stabilize his workforce, Ford announced the $5 dollar day. “This was not a simple wage increase,” wrote Stephen Meyer “but a sophisticated profit-sharing scheme to transform the social and cultural lives of immigrant workers and to inculcate the life-style, personal habits, and social discipline for modern factory life.”36 Ford used methods inspired by the Progressivism of the early twentieth century to stipulate how families should take care of their homes and how single men should take care of themselves.37 From 1914 to 1921 Ford embarked on a social experiment steeped in a paternalism that aimed to “Americanize” the immigrant workforce. While immigrants were willing to work in coal mines, iron and steel mills, meatpacking plants, and tanneries, in addition to automobile factories, they lacked industrial experience. When WWI ended the flow of European immigrants into Ford factories, recruitment of Black and White rural Americans became the norm.

Ford aimed to eliminate the lackluster “dude employee,” who talked and walked more than he worked. The application of scientific management to achieve mass production required a regulated “human element.” From 1920-1923 the assembly line underwent a “speed-up.” The pace of the assembly line was grueling, and in addition, smiling, laughing, and sitting were prohibited. But factories were safe, ventilated, and well lit. Nevins and Hill observed that, “as in all mass production industries of the time, they were the rules of an army, not of a cooperative community.”38 Joyce Shaw Peterson argued that while Ford was union free from 1903 to 1933, workers used turnover rates, absenteeism, restriction of output, and walkouts to convey disapproval.39 Autoworkers accepted the high wages, adopted the new habits, and endured the degraded labor.

Historians have given a fair amount of attention to Black labor in the automobile industry.40 The demographic shift inspired by Ford’s factories provided reason for Blacks to migrate to Northern industrial centers. In 1917 Packard employed 1,100 Blacks, but Ford quickly overtook Packard and employed 5,000 Blacks in 1923 and 10,000 by 1926.41Despite Henry Ford’s personal racial outlook that Blacks were racially inferior and should remain segregated, his factories were interpreted as places of inspired racial uplift. Ford felt that the superior race was obligated to facilitate the uplift of subordinate races with philanthropic services, and this earned him a reputation as a friend of the Black race. Yet, life for Black workers in Detroit remained mixed.

Joyce Shaw Peterson historicized the new Black industrial community forged in Detroit. Despite high wages, most African Americans were segregated at the plant and in life outside of it.42 When Peterson inquired, “Apart from their existence inside the factory walls, what kind of life did black auto workers find in Detroit?” she answered with frustrating segregation, higher rates of disease, and overcrowded housing. In an industrial city the comforts of the home were paramount to the ability to endure monotonous and dirty work. Peterson noted that “migrants confronted the ironic situation of earning much better wages than they ever had before and still being unable to rent decent lodgings.”43 For Blacks, “segregated housing patterns . . . not only were blows to comfort, pride, self-esteem and family life; they could also kill.”44 Peterson concluded that more racial tension existed in Detroit due to residential patterns and competition for housing than over jobs. Beyond the factory and housing, entertainment facilities, and recreational activities provided by the companies, such as sports leagues; were segregated. Peterson noted that, “by far the most important social institutions were black churches,” which “became the most vital institution trying to both integrate rural blacks into the urban atmosphere and cement and develop a sense of racial community.”45

In Black Detroit August Meier and Elliot Rudwick noted, “the income of Ford’s Black workers was the cornerstone for the prosperity of the black community’s business and professional people.”46 Blacks “were employed in the laboratories and drafting rooms; as bricklayers, crane operators, and mechanics; and . . . as electricians and tool-and-die makers.”47 James C. Price became an expert in purchasing abrasives and diamonds.48 Eugene J. Collins became head of the die casting department in 1924, and was later named the first Negro foreman.49 Meier and Rudwick point out that, “Ford established his own contacts among key black leaders, especially among the clergy.”50 Ford’s paternalism extended to local African American communities. This won Ford praise from African Americans, so much so that “black workers at Ford felt themselves superior, and wore their company badges to church on Sunday.”51

African Americans comprised a significant portion of Ford’s workforce. James Flink pointed out that, “Ford’s black workers were concentrated at the Rouge, where by 1926 they number 10,000 and constituted about 10 percent of the work force.” At the Rouge, African-Americans were concentrated in “the most dangerous, dirty, and disagreeable jobs – chiefly in paint spraying and foundry work.”52 Blacks were employed in positions that required the greatest physical exertion, the highest accident rates, and most exposure to health hazards. Despite the racial victories of foremen like Eugene J. Collins, most Blacks were forced into hazardous jobs in separate parts of the factory.

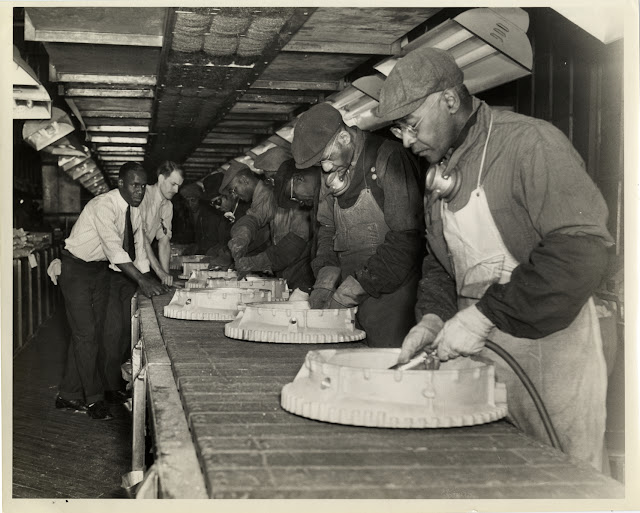

View of men working on assembly line in Packard Motor Company factory. Handwritten on back: "Manufacturing scenes. Factories--Packard, 1939” Photograph from Detroit Public Library

Ford countered the critics of mass production in his own time in his 1926 article on the topic in Encyclopedia Britannica. He argued that

The need for skilled artisans and creative genius is greater under mass production than without it. In entering the shops of the Ford Motor Co., for example, one passes through great departments of skilled mechanics who are not engaged in production, but in the construction and maintenance of the machinery of production. Details of from 5,000 to 10,000 highly skilled artisans at strategic points throughout the shops were not commonly witnessed in the days preceding mass production. It has been debated whether there is less or more skill as a consequence of mass production. The present writer’s opinion [Ford’s] is that there is more. The common work of the world has always been done by unskilled labor, but the common work of the world in modern times is not as common as it was formerly.53

Fordism completed a revolution in the making of things that originated with the notion of interchangeable parts first proposed by Eli Whitney in 1798. Combining the practice of interchangeable parts as employed in nineteenth century armories with that of the moving disassembly line in the meat packing industry and techniques involving metal stamping from the bicycle industry, the assembly line led to what is called deskilling and monotony. But Fordism had its advantages. Fifteen million Model Ts were produced by 1927, and profits exceeded $7 billion.54 The following chart shows the actual production volume at Ford from 1903 through 1927.55

Year | Number of Cars | Year | Number of Cars |

1903 | 1,708 | 1916 | 734,811 |

1904 | 1,695 | 1917 | 622,351 |

1905 | 1,599 | 1918 | 435,898 |

1906 | 8,729 | 1919 | 820,445 |

1907 | 14,887 | 1920 | 419,517 |

1908 | 120,202 | 1921 | 903,814 |

1909 | 17,771 | 1922 | 1,173,745 |

1910 | 32,053 | 1923 | 1,817,891 |

1911 | 69,762 | 1924 | 1,749,827 |

1912 | 170,211 | 1925 | 1,643,295 |

1913 | 202,667 | 1926 | 1,368,383 |

1914 | 308,162 | 1927 | 352,288 |

1915 | 501,462 |

Ford and the Ford Motor Company’s accomplishments were more than simply making complex mechanical things in quantity, however. As Anthony Patrick O’Brien has demonstrated, beginning around 1910 or 1911 Ford also pioneered controls on mass distribution in the automobile industry.56 “Telegraphic ten day reports” were sent by branch managers to Detroit summarizing current dealer stocks, production levels, and dates of customer purchases. Later data that also included the number of salesmen employed and live prospects on file came from dealers. This accounting system was in part responsible for Ford weathering recessions in 1910-11 and 1920-21 far better than its competitors. And contrary to the interpretation that it was General Motors that developed a tight connection between production and distribution by the mid-to-late 1920s, it appears that Ford did it first. Ultimately then, GM’s eclipse of Ford by the late 1920s was not due a process control and distribution network advantage, but rather to the fact that GM offered more products in more price ranges. After all, while GM during the 1920s was trying to anticipate what customers wanted in a car, Henry Ford staunchly remained convinced that only he had the right idea about what a car should be.

By the early 1920s, there would be not just one Ford Model T assembly line, but many, in factories all over America. Surprisingly, perhaps, the factory with the largest output during the 1920s was not the Highland Park facility, but one located in Kearny, Nebraska. Large facilities were also located in Atlanta, Buffalo, Cambridge, Chicago, Cincinnati, Columbus, Dallas, Des Moines, Houston, Indianapolis, Kansas City, Louisville, Memphis, Milwaukee, Minneapolis, Oklahoma City, Omaha, Philadelphia, Pittsburgh, San Francisco, Seattle, and St. Louis.57

Henry Ford also demonstrated his genius by implementing the $5 day in 1914. While economists and industry experts asserted that Ford’s $5 day would lead to his bankruptcy, Ford’s motives were based on common sense mixed with a vision of the firm in which returns on investment were not maximized, but rather acceptable. It was both good business and an expression of concern for the common man. The assembly line in its early days had already led to an unacceptable labor turnover rate; in response, Ford raised hourly wages so that workers would stay despite the repetitive and exhausting nature of the job. And if a worker didn’t like conditions, there were many – Poles, African Americans, and other minorities – outside the gates waiting to replace anyone dissatisfied. The $5 day was just another reason why many viewed Ford as a hero. As Ford correctly recognized, the $5 day resulted in more business, not only as his own workers bought Model Ts, but also for service industries that provided for line workers and their families. Ford had envisioned and then implemented a giant technological and economic feedback loop that accelerated his own profits while stabilizing his labor force.

No comments:

Post a Comment